GEO EXPLORATION SOLUTIONS FZC - GES – manufactures advanced

geophysical systems for special tasks, like geoelectrical real-time

ahead monitoring for tunnel boring machines as well as helicopter-based

electromagnetic exploration systems for oil, ore and geothermal anomaly

identification.

Airborne Seismo-Electromagnetic Surveys

HYDROSCAN survey results by helicopter:

Oilfield, offshore

Oil & Gas Exploration

HYDROSCAN® is an innovative helicopter-borne seismo-electromagnetic exploration technology for detection and imaging of hydrocarbon (HC) accumulations up to depths of more than 4.000 m.

HYDROSCAN survey enables the differentiation between presence and absence of HC reservoirs as well as a relative productivity characterisation in onshore and offshore areas.

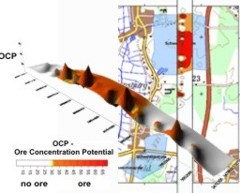

ORESCAN survey results by helicopter:

Ore deposit, onshore

Detection & Imaging of Ore Deposits

ORESCAN® opens a wide range of highly beneficial usage for the mining industry, from frontier exploration to mine extensions, from prospect derisking to optimization of drilling placement.

Differentiation between presence or absence of ore mineral deposits like gold, sulphidic and conductive ore as well as rare earth minerals for instance up to depth of about 300m.

Determination of the Ore Concentration Potential (OCP) as a relative quantity.

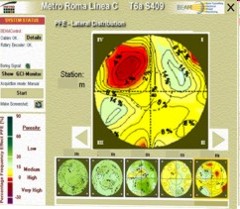

Lateral distribution of Signal Power values, e.g. represented in contour plots.

Full range of geophysical services of surveying, processing, evaluation, modeling, interpretation, documentation, visualisation and reporting of results are exclusively provided across the world by GES.

Real-time Ground Prediction While TBM Tunnelling

BEAM real-time forecast results ahead of the

face in 3-times the TBM diameter

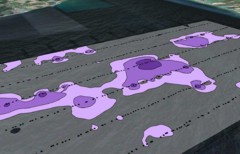

Geoelectrical Ahead Monitoring

BEAM® is a non-intrusive focused-electrical induced polarisation ground prediction technique, permanently operating while TBM tunnelling.

It´s an early detection and warning system of changes in geotechnical-geological and hydrogeological ground conditions like fault/karst zones, cavities or permeable water-/gas-bearing zones.

Since 2000 until the first half year of 2023, the BEAM system has proven itself in more than 70 tunnel projects

with 101 TBM drives in 21 countries and more than 300 km of excavated tunnels

worldwide. It is designed for the rough conditions of tunnelling and works properly in any geology and can be easily installed in any type of TBM, independant of TBM supplier.

BEAM is the world-leading system for permanent and real-time ground prediction in TBM projects.